MRDC Systems are the key to maintaining and extending the life of HV power cable systems. USi helps utilities to manage underground T&D assets more efficiently by delivering integrated solutions based on decades of experience with sensors, data acquisition, advanced hardware, communications, analytics and displays. USi pioneered MRDC technologies on HV power cable systems of all types. We offer a variety of MRDC systems including:

Cable System Monitoring, Diagnostic Alarm and Control Systems (MDACS)

MDACS is a condition-based maintenance tool providing customers with the capability to monitor and control their power cable system remotely from a centralized location. Designed and integrated into customer operations by USi, MDACS allows customers to monitor Pressurization Plants, Dielectric Fluid Chiller Plants as well as remote devices including Pothead Leak Detection and Pressure Alarms, Feeder Loads, Pipe Temperatures, Earth Temperatures and Cathodic Monitoring within the power cable system.

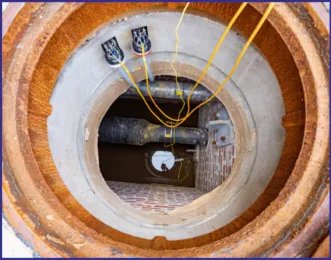

Cathodic Protection Monitoring Systems

Virtually all underground pipe-type cable systems have cathodic protection (CP), however corrosion remains the most likely cause of shortened cable life. USi Cathodic Protection Monitoring Systems cut maintenance costs and increase maintenance quality at the same time, facilitating the discovery of CP system problems before they lead to service interruptions and significant repair costs.

The USi CP-Watch Cathodic Monitoring System measures critical CP System parameters every few seconds, and issues alarms when values fall outside the expected range.

Leak Detection and Location

USi provides high sensitivity leak detection systems (HSLDS) capable of detecting leaks at or below 1 gph using a proprietary model. The HSLDS has been developed over the past 20+ years and has a proven accurate and reliable operational history at a number of electric utilities.

PFT Leak Location technology is the state of the art means for finding fluid leaks in many types of buried cables. USi working with Con Ed, EPRI and Brookhaven Lab first helped develop and then commercialized the technology.

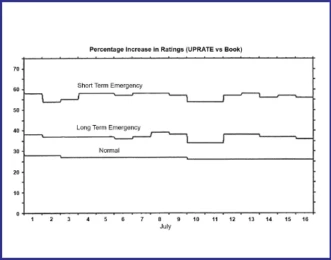

UPRATE™ Dynamic Rating Systems for Cables

UPRATE™ thermal monitoring and ratings system use real-time temperature measurements and thermal models to provide dynamic ratings. It dramatically increases the ratings over “book” value for both overhead and underground cables. Transmission capacity is not only increased, but made safer because the UPRATE™ system computes capacity based on actual cable component temperature and environmental conditions, rather than assumptions.

USi installed the first commercial system in 1986 and has since applied the UPRATE technology to all types of cable systems including solid dielectric, high pressure pipe type and self-contained fluid filled.

DOWNLOAD

To learn more about Monitoring, Ratings, Diagnostics and Controls, please download the PDF Brochure.