Product Overview

As a leader in the design and manufacturing of high voltage cable accessories for over 45 years, USi has the resources and experience to meet any accessory need, from extra-high voltage to low voltage, high pressure pipe-type to low pressure self-contained and solid paper to low pressure gas . The following is an overview of USi’s capabilities;

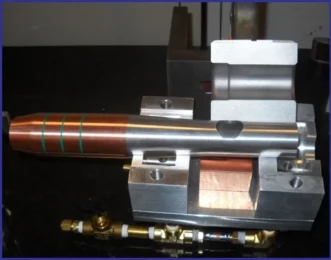

Custom-Designed Joint Kits and Components

USi custom designs joint kits for cables rated from 5 kV to 500 kV. They are available for pipe-type, self-contained, and solid paper insulated cables. Insulations include low power factor, high dielectric strength flat and crepe paper, PPP semi-synthetic laminate and polymeric tapes. Kits are supplied complete, including all components, accurate instructions and detailed drawings prepared for the specific installation.

Terminations and Termination Products

USi supplies high voltage terminations for high, medium and low- pressure dielectric fluid-filled – and high pressure, gas-filled cable systems, rated up to 230 kV. They are designed to meet IEEE Standard No. 48 requirements. USi designs and manufactures accessories for terminations, including diffusion chambers, insulated mounting plates, external filter bypass assemblies and termination pressure monitoring and alarm assemblies. Custom design services are available for termination interfaces with transformers and switchgear. USi also designs and fabricates stainless steel risers and couplings needed in the station. USi can do the complete job including the engineering calculations, riser bend layout between the trifurcator and the termination stub, as well as providing pre-bent riser pipe sections for easy assembly in the field.

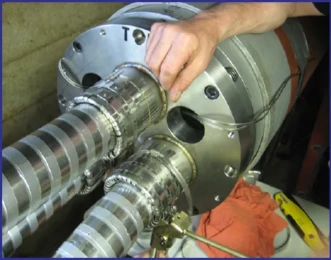

Custom-Designed Joint Casings, Pipe-Type Cables

Each USi joint casing is designed to work in its installation environment (e.g. a specific manhole or buried pipe-type cable application) to prevent thermal mechanical damage from occurring in the splice and cable and to provide adequate room for installation. Evacuation, drain and pressurizing valves are included when required. Normal and special casings (trifurcators, spreaderheads and diffusion chambers) are also available. Sleeve assemblies and component parts for self-contained and lead-jacketed cables are available in many configurations with materials including carbon steel, stainless steel, lead, copper and aluminum.

HPPT Full Stop Anchor Joints

Suitable for voltages up to 345 kV, the USi Full Stop Anchor Joint is designed to provide full hydraulic separation across the joint. The “Stop” feature of the FSAJ product acts as an in-line valve, capable of stopping 100% of the cable pipe fluid flow while maintaining the integrity of the cable system. This “valve” can be operated manually or automatically to completely stop the flow or can be throttled to limit the flow of dielectric fluid. The FSAJ is designed around the use of proprietary cast epoxy insulators and proprietary O-ring seal designs to provide complete hydraulic separation across the joint. The joint has been designed and tested to a differential pressure of 500 psig as well as being qualified to the electrical requirements of IEEE 404 up to the 345kV level (+/- 1300kV BIL). The FSAJ also has the added benefit of providing an anchor feature to the cable which is used to limit down-hill creep for cables in pipes that have been installed on relatively steep inclines. Cross-over piping is provided to allow the fluid pressure to bypass around the Full Stop joint in its normal operating configuration. The cross-over can be configured in a number of ways for either normal/static operation or sized for slow or fast (forced cooled) circulation. Valves and manifolds can be designed for installation either above or below grade as well as provided for manual or remote electrical operation from the utility’s control room.

XLPE to HPPT Transition Joints

Transition joints represent a cost- effective option for circuit expansion or diversion, a USi transition joint can be designed and supplied whenever there is a requirement to merge an existing HPPT cable with solid dielectric cable. This might be necessary where cables pass over or under waterways, substation hardening, flexibility for transformer or bus replacements. Conductor materials and/or cross sections on each cable type can be different. Suitable for voltage class in the range up to 138 kV.

![]() Download Pre-moulded CLICK-FIT® XLPE to HPFF Transition Joint Product Sheet

Download Pre-moulded CLICK-FIT® XLPE to HPFF Transition Joint Product Sheet

Protection for Terminations During Loss of Pressure

All high pressure terminations are susceptible to failure when internal pressure drops below the allowable operating minimum. USi’s SF6 Termination Injection System (TIS) provides immediate protection following catastrophic pressure loss. Recent application has been on high pressure pipe systems where large elevation differences exist between terminal ends. The SF6 TIS can easily be incorporated in both new and existing termination assemblies.

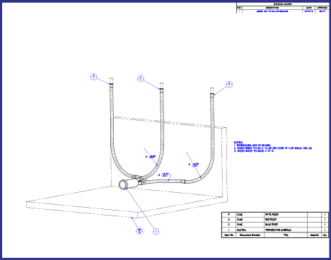

Valve and Pipe Assemblies

USi designs and fabricates fail-safe crossover assemblies, outlet valve manifolds, diffusion chambers, flow limiters, automatic bypass units and other custom valve, pipe and instrumentation assemblies. All high-pressure assemblies are manufactured under a certified USi quality control program and are fully factory tested. USi cross-over and bypass valve assemblies can be fully instrumented and self-contained. They automatically close or limit flow upon sensing a leak, a major pressure loss or a pressurizing plant problem. Used in combination with USi stop joints, this system allows the stop joint to be fully automatic, providing stop joint protection within seconds entirely without manual intervention.

Technical Support and Training

USi fully supports its customers during and after installation, including training customer staff, assisting during startup and with technical help if there are ever any problems. USi personnel have spliced cable in manholes and at sea, repaired cable failures, repaired and refurbished terminations and located leaks. There is no substitute for field experience for solving problems in the field.

DOWNLOAD

To learn more about High Pressure Pipe Type Cable Accessories, please download the PDF Brochure.